1.8 meter intelligent joint stamping manipulator

QF-MD-1800 intelligent joint stamping manipulator

Suitable for the multi-press connection site of tonnage within 350T, and the one-machine multi-mode punching machine within 1250T.

The size of the grabbed product is recommended to be within 1000*1000 mm.

Suitable for stamping sites of electronic products, home appliance parts, mechanical parts and auto parts.

At the same time, it is suitable for the palletizing and depalletizing of common sheet materials.

Effectively solve the picking and placing of materials within 100KG. The arm span can reach 3.1m, and the efficiency can reach 8-20 times/min.(Depending on the manipulator model and production environment)

With path programs such as material palletizing and depalletizing, it is suitable for the stacking, depalletizing and handling of common materials.

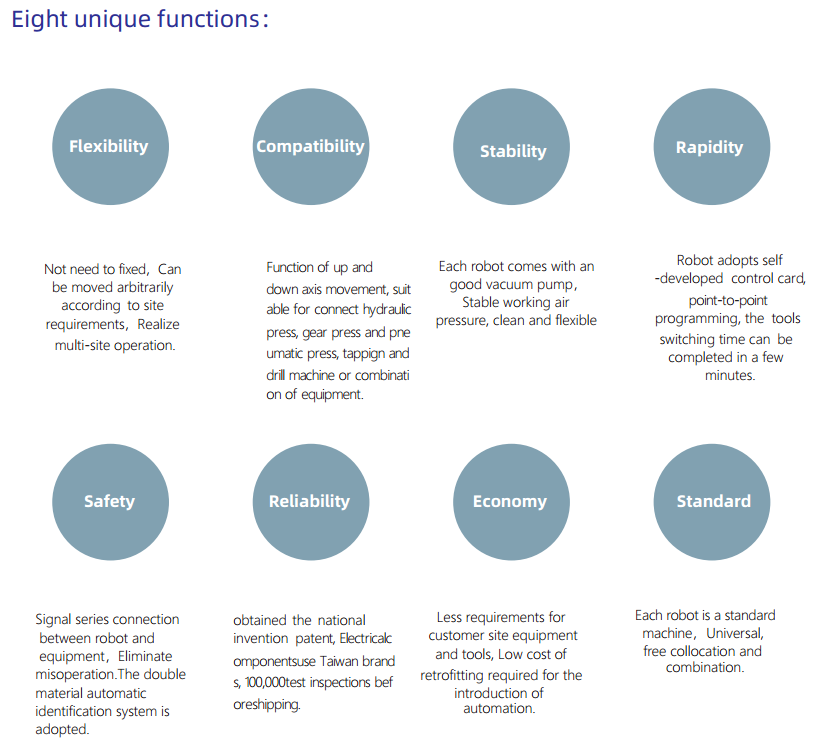

With high flexibility, it can realize various stamping actions in all directions and from multiple angles: flipping, scrapping (before discharging), side hanging, oblique placing, stacking, and etc. It is also suitable for continuous mold, single machine multi-mode and other mold processes.

Each axis adopts a high-performance absolute servo system, the circuit is optimized, and the overall performance is excellent. At the same time, it has a power-off position memory function to avoid the trouble of returning to the origin.

Adopt open programmable technology, support motion track editing, simple operation, flexible control, can store a variety of product information with strong interchangeability. One-time setting can be used for a long time.

It is suitable for all types of stamping equipment on the market: gear punch press, pneumatic punch press, hydraulic press, and can be connected at will regardless of the tonnage or the height of the machine to realize the free combination and connection of equipment.

Using well-known brands at home and abroad and high-precision core accessories, the quality is stable and reliable, the positioning error is controlled at ±0.1mm, the failure rate is lower than 1‰, and the service life is 8-10 years (Depending on the production environment and maintenance conditions)

The product is highly standardized and only need to customize the gripper (suction cup type, pneumatic type, magnetic suction type, etc.). It’s easy to install, and can be mass-produced within three days of delivery.

|

Model |

QF-MD-1800 |

|

|

Parameter |

Unit |

Index |

|

Voltage |

V |

AC 380 |

|

Power frequency |

Hz |

50/60 |

|

Power |

KW |

7 |

|

Working temperature |

℃ |

-20~45 |

|

Relative humidity of working enviroment |

% |

20~80 |

|

Max. working radiu |

mm |

1800 |

|

Min. working radiu |

mm |

350 |

|

Max. precision repeatability |

mm |

±0.1 |

|

Grip weight |

kg |

≤25 |

|

The max. range of each joint movement |

0 |

J1±160⁰ |

|

0 |

J2+75⁰, -35⁰ |

|

|

0 |

J3+75⁰, -25⁰ |

|

|

0 |

J4±300⁰ |

|

|

The max. speed of each joint movement |

⁰/S |

J1 174.7 |

|

⁰/S |

J2 162.1 |

|

|

⁰/S |

J3 171.3 |

|

|

⁰/S |

J4 455.6 |

|

|

Robot weight |

kg |

≈390 |

Inquiry Now

Related Products

3.1 meter intelligent joint stamping manipulator

3.1 meter intelligent joint stamping manipulator

QF-MD-3100 intelligent joint stamping...

1.4 meter intelligent joint stamping manipulator

1.4 meter intelligent joint stamping manipulator

QF-MD-1400 intelligent joint stamping...

1.2 meter intelligent joint stamping manipulator

1.2 meter intelligent joint stamping manipulator

QF-MD-1200 intelligent joint stamping...